Farewell this weekend, as we start to say good bye to one of Swindon Panel’s neighbours – the first part of the Stoke Panel in Bristol PSB has been decommissioned and is being recontrolled to TVSC.

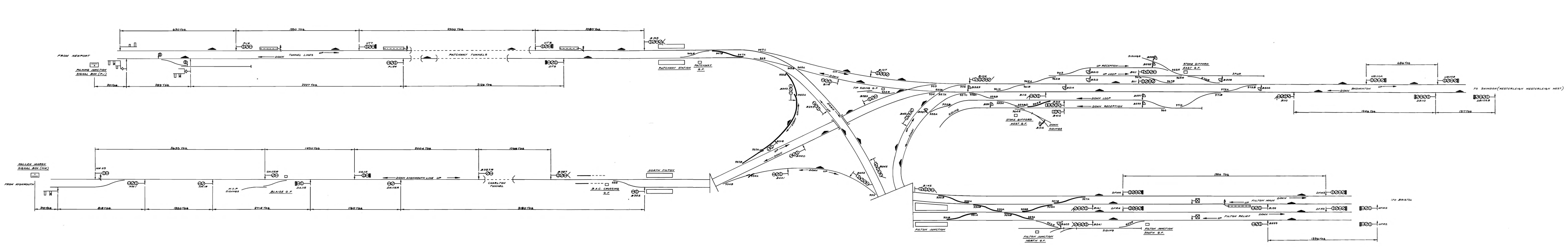

The lines moved are those that were commissioned under stage 7B of the Bristol MAS scheme on 22 February 1971: Winterbourne to Patchway, Filton Jn and Hallen Marsh. It replaced the boxes at Filton Junction, Filton West, Stoke Gifford East, Stoke Gifford West, Patchway and Cattybrook.

The map of Stage 7B of the Bristol MAS scheme in 1971. Click for a larger version.

Bristol Stoke will still control, for the time being, the Charfield lines to the fringe with Gloucester and the Badminton lines fringed by TVSC on both sides (in the east where it used to fringe with Swindon PSB.) This area would have been decommissioned some time ago, but was delayed by the delays to the closure of Swindon PSB.

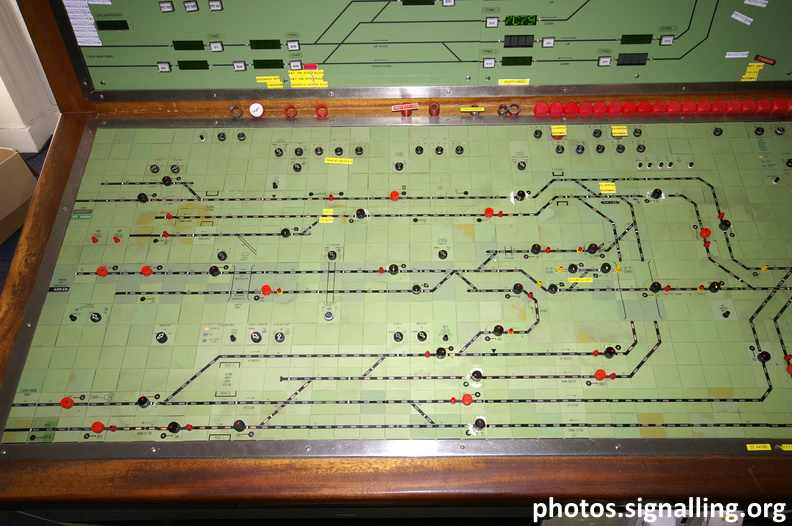

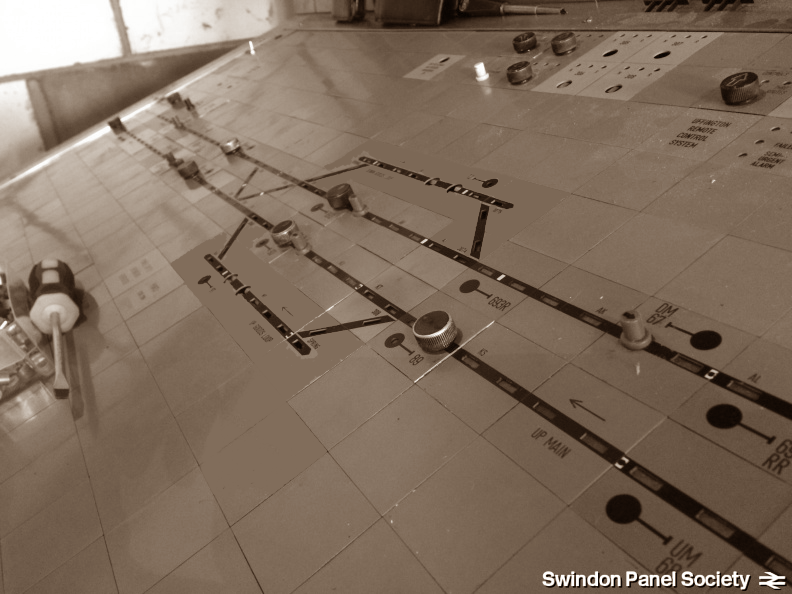

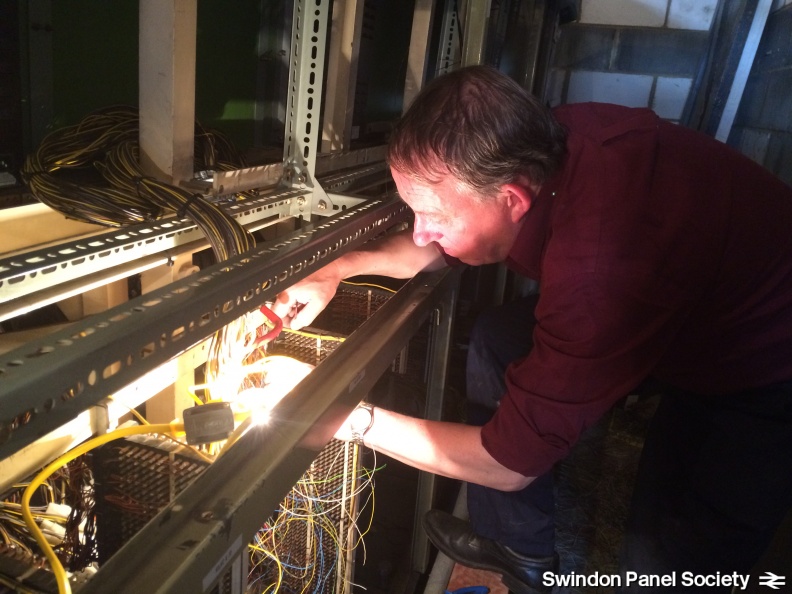

The photos above show two parts of Bristol Stoke Panel in 2007.

When the Bristol MAS scheme was started in 1970 BR proudly launched a large public awareness campaign called “Starting Something Big at Bristol”, with large banners at the front of Temple Meads station. Bristol was the largest panel box Western Region had ever installed, they were proud of it, and wanted everyone to know.

The campaign distributed information to the public about the scheme and how it would improve the management of rail traffic, and managed their expectations about the necessary service alterations that would take place during the process. Open meetings were held for the railwaymen and women of the time to attend and raise questions etc about the scheme. As with all large-scale industrial changes such as this there was some considerable upheaval for the staff concerned, not unlike the present-day scheme. One of the then-signalmen, Peter Randall, wrote an excellent contemporaneous book about the resignalling and the social and operational impact that shared the name “Starting Something Big at Bristol”.

The current resignalling, slightly less proudly called “BASRE” (Bristol Area Signalling Renewals and Enhancements), is driven by three main factors: life-expiry of the 1971 equipment, the requirement for AC-immune signalling in readiness for electrification, and the re-four-tracking of Filton Bank to deliver capacity enhancements. The scheme, which includes Bristol Temple Meads and everything north and east thereof, will require over 700 signalling equivalent units (SEUs). A large number of WR MAS gantries and cantilevers will be replaced, connections to a new IEP depot at Stoke Gifford will be commissioned, and the St Andrew’s Crosses at Temple Meads with mid-platform signals, and of course all the WR E10k electro-mechanical relay interlockings will be replaced with solid-state interlockings, relocked and recontrolled to TVSC under the ‘85% compliance approach’ which means existing signal positions remain largely unchanged.

If you have memories of working in Bristol Panel or on the Bristol area, or photos from the panel, especially in its early days, please do share them with us in the comments below.

Good luck to everyone involved in the decommissioning, the commissioning, and the well done to everyone who has worked in Bristol Panel, upstairs, downstairs, or outside, over the last 45 years.

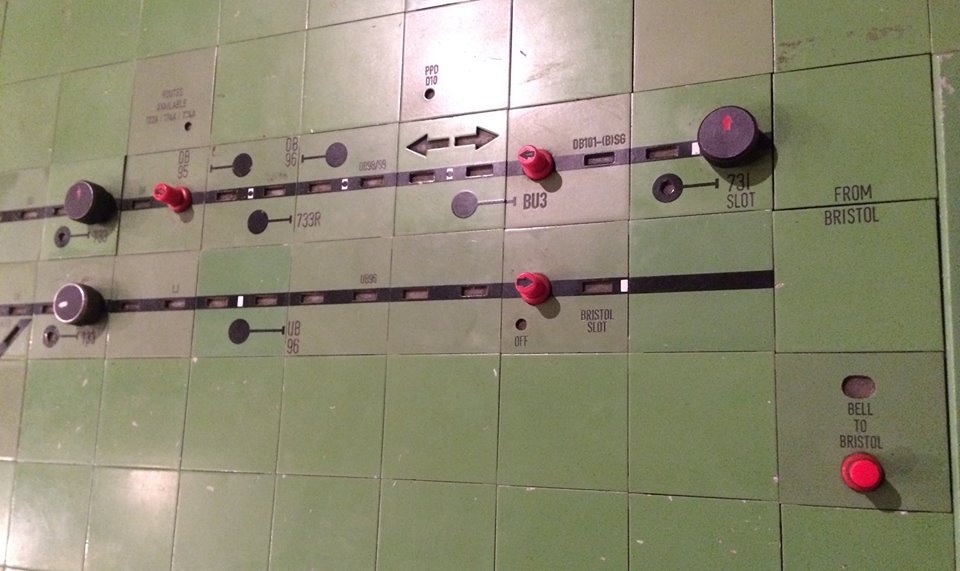

The photo below shows Swindon Panel’s fringe to Bristol Stoke.